Sugeng rawuh ing CHUANGRONG

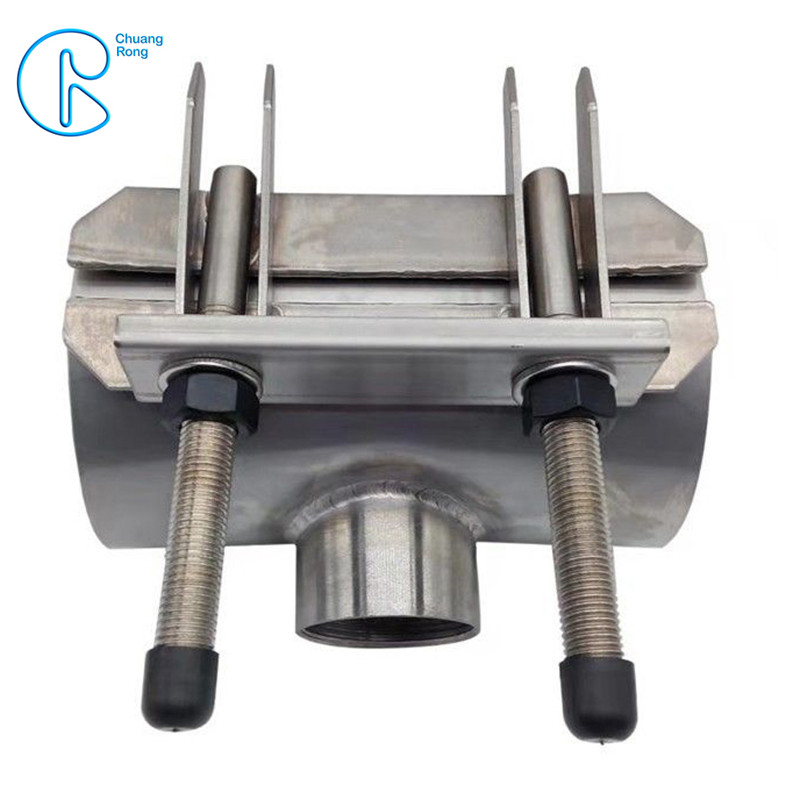

Pipa Repair Clamp Stainless Steel Multi-Fungsi Tee Produk Repair Bocor

Informasi Detail

| Bahan: | Baja tahan karat | Wangun: | Tee |

|---|---|---|---|

| Bahan: | AISI 304 | Fungsi: | Repair Pipa Bocor |

| Teknik: | Stamping lan Welding | Tipe: | RCD-T CRT-1 |

| Komponen/Material | M1 | M2 |

| Kulit | 304 / 304L | 316 / 316L |

| Jembatan Plate | 304 / 304L | 316 / 316L |

| Plat Persimpangan | 304 / 304L | 316 / 316L |

| Lugs | 304 / 304L | 316 / 316L |

| Plat Pengunci | 304 / 304L | 316 / 316L |

| Bolt $ Nut | 304 / 304L | 316 / 316L |

- Waca AS 4181-2013, DIN86128-1/2, CB/T4176-2013

Deskripsi Produk

Fitur produk:

1, Jinis band utama klem ndandani yaiku pipa wesi, baja, tabung semen, PE, PVC, tabung baja kaca lan liya-liyane macem-macem pipa pecah, perforasi, lan kabeh jinis karusakan retak nyedhiyakake cara ndandani sing cepet lan ekonomi bisa nyuda biaya bahan lan tenaga kerja.

2, Instalasi produk iki trep, cepet, mung perlu siji wong, kunci bisa gampang rampung repair pipe, ora maneh perlu nomer akeh buruh, bisa ora mandheg rampung, ora ngganti meksa pipe saka piping repair cepet, busur bunder saka syarat gelar kanggo pipe kurang.

3, Bahan stainless steel, duwe anticorrosive, kateguhan dhuwur, atose lan karakteristik liyane.

4 , Tipe Band klem repair duwe ring sealing pindho, mburi menyang tapered, anggere iku ing orane katrangan saka ukuran hoop gegaman, ngendi kabeh bisa éling tumpang tindih efektif, segel seragam.Sealing ring sruface kanggo bolong nggoleki, bisa adaptasi kanggo atos, lumahing ora duwe aturan baku pipo keropos, watara kabeh pipeling sealing wangun bunder efektif.

5, Produk iki nggunakake mode sambungan jinis gesper kertu, lan diameteripun cocok paling gedhe produk orane katrangan bisa nganti 30 mm, bisa nemen ngurangi persediaan, specification produk bisa saka DN1500-repair jembaré bisa nganti 2000mm, meh bisa ketemu ukuran pipe.

Kanggo klem repair stainless steel

1), badan penjepit: baja tahan karat SS 304.

2), baut lan mur: baja tahan karat SS 304.

3), karet: NBR/EPDM.

3), karet: NBR/EPDM.

4), Locking washer palte, Lugs, Receiver bar, Armor: stainless steel 304

5). Tekanan kerja: PN10-PN16

6). packing: kasus kayu

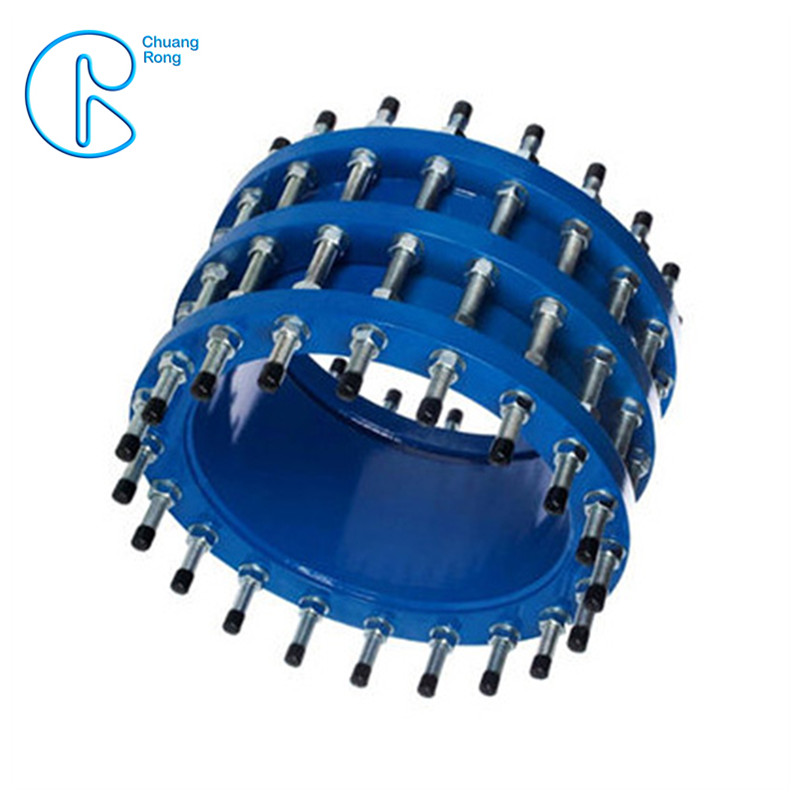

Kanggo klem ndandani DI

1), bagean clamp casting: wesi ulet GGG500-7 karo fusion bonded lapisan epoxy

2), baut lan mur: Baja karbon, Grade 4.8, seng dilapisi.

3), karet: EDPM.

4), badan penjepit: Baja tahan karat SS304.

5). Tekanan kerja: PN16

6). packing: kasus kayu

GUNA

1) Clamps dirancang kanggo digunakake ing pipa udara, banyu lan gas.

2) Clamps minangka produk khusus sing cocog kanggo pipa baja SABS 62, pipa PVC metrik lan kekaisaran.

Bahan Konstruksi

1) Shell-Stainless Steel 316

2) Bolts-Steel kanggo BS970 Grade 070M20

3) Bolt coating-seng dilapisi

4) Rubber Seal-EPDM kanggo SABS 974

Spesifikasi

| DN | Range | Dawane 300mm | Dawane 400mm | Dawane 500mm | |||

| Max Tee Drilling | Tekanan | Max Tee Drilling | Tekanan | Max Tee Drilling | Tekanan | ||

| 80 | 88-110 | DN65 | PN10/PN16 | DN65 | PN10/PN16 | DN65 | PN10/PN16 |

| 80 | 100-120 | DN65 | PN10/PN16 | DN80 | PN10/PN16 | DN80 | PN10/PN16 |

| 100 | 108-128 | DN65 | PN10/PN16 | DN80 | PN10/PN16 | DN80 | PN10/PN16 |

| 100 | 114-134 | DN65 | PN10/PN16 | DN80 | PN10/PN16 | DN80 | PN10/PN16 |

| 100 | 120-140 | DN65 | PN10/PN16 | DN80 | PN10/PN16 | DN80 | PN10/PN16 |

| 100 | 130-150 | DN65 | PN10/PN16 | DN80 | PN10/PN16 | DN100 | PN10/PN16 |

| 125 | 133-155 | DN65 | PN10/PN16 | DN100 | PN10/PN16 | DN100 | PN10/PN16 |

| 125 | 135-155 | DN65 | PN10/PN16 | DN125 | PN10/PN16 | DN125 | PN10/PN16 |

| 125 | 140-160 | DN65 | PN10/PN16 | DN125 | PN10/PN16 | DN125 | PN10/PN16 |

| 150 | 158-180 | DN65 | PN10/PN16 | DN125 | PN10/PN16 | DN125 | PN10/PN16 |

| 150 | 165-185 | DN65 | PN10/PN16 | DN125 | PN10/PN16 | DN125 | PN10/PN16 |

| 150 | 168-189 | DN65 | PN10/PN16 | DN125 | PN10/PN16 | DN125 | PN10/PN16 |

| 150 | 170-190 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 150 | 176-196 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 150 | 180-200 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 150 | 190-210 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 150 | 195-217 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 150 | 205-225 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 200 | 210-230 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 200 | 216-238 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 200 | 225-246 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 200 | 230-250 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN150 | PN10/PN16 |

| 225 | 240-260 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

| 225 | 250-270 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

| 250 | 260-280 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

| 250 | 269-289 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

| 250 | 273-293 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

| 250 | 283-302 | DN65 | PN10/PN16 | DN150 | PN10/PN16 | DN200 | PN10 |

Carane milih

Konfirmasi pipa OD lan titik bocor sing pengin didandani. Pilih jinis clamp tengen (band siji utawa pindho, jembaré utawa dawa etc). Pilih ukuran sing pas kanggo pipa OD Sampeyan bakal ndandani. Contone, nalika pipa OD ≤300mm, clamp sing sampeyan pilih kudu 80mm luwih amba saka titik bocor. Nalika pipa OD≥300mm, dawane kudu paling sethithik 100mm kanggo nutupi titik bocor.

Sawise ndandani urgert perlu rampung ing pipo lagrg, klumpuk sawetara Clamps sawetara cilik kanggo siji sawetara Klem repair band.

1. Priksa manawa pipa OD sing tepat, sing kudu didandani.

2.Pilih loro utawa telu sawetara Clamps cilik, priksa manawa jumlah saka sawetara padha karo O.Dof pipo sing arep kanggo ndandani. Contone, nalika repraiing a DN500mm DI pipe, O.D510mm, milih telung Clamps DN150 kang sawetara 159-170 kanggo nggawe ukuran tengen kanggo DN500 iki.

3. Clamps cilik sing digunakake kanggo ngumpul dadi gedhe ora perlu ukuran sing padha, nanging bakal luwih apik.

Instruksi Instalasi

1. Waca kanthi apik sadurunge nginstal . Priksa bagean kanggo mesthekake yen ora ana karusakan nalika transit lan ora ana taman sing ilang. Priksa dimeter pipa lan spesifikasi clamp (ing label) kanggo mesthekake yen sampeyan duwe clamp sing cocog kanggo aplikasi sampeyan.

2.Resik lan ngilangke sembarang irregularities ing pipe ends.

3. Ing saben ujung pipa, gawe tandha ing jarak sing padha karo setengah jembar kopling.

4. Tanpa mbukak kopling, geser kopling ing mburi pipa.

5. Nggawa pipa liyane mburi popsition madhep. Priksa manawa pipa didadekake siji concentrically lan loro pipe ends curreclty didhukung. Waca toleransi sing dituduhake ing label.

6. Selehake kopling antarane tandha lan priksa manawa waja ing bolts. Aja ngluwihi syarat torsi sing dituduhake ing label produk.

7. Ngencengi bolts gantian lan roto-roto kanggo torsi dibutuhake. Yen ana telung bolts, miwiti karo bolt tengah, lan miwiti tightening. Aja muter kopling utawa pipa sak utawa pungkasan tightening.

Aplikasi

Pipa Minyak Mentah, Pipa Gas/Gas Alam/Bahan Bakar, Pipa Air Supply/Draign, Pipa Khusus Penerbangan/Otomotif, Pipa Minyak Pelumas, Pipa Mud slag, Pipa Suction, Pipa Daya Flushing, Pipa proteksi kabel, Pipa Air Laut/Tawar, Pipa Turbin, Pipa AC, Pipa Udara Ventilasi dll.

CHUANGRONG duwe tim staf sing apik banget kanthi pengalaman sing sugih. Pokoke yaiku Integritas, Profesional lan Efisien. Wis nggawe hubungan bisnis karo luwih saka 80 negara lan zona ing industri relatif. Kayata Amerika Serikat, Chili, Guyana, Uni Emirat Arab, Arab Saudi, Indonesia, Malaysia, Bangladesh, Mongolia, Rusia, Afrika lan sapiturute.

Yen sampeyan duwe pitakon, sampeyan bisa ngubungi kita kapan wae.

Sugeng rawuh kanggo hubungi kita kanggo rincian produk lan layanan profesional.

Mangga ngirim email menyang:chuangrong@cdchuangrong.comutawa Tel:+ 86-28-84319855

Kirim pesen kanggo kita:

Kategori produk

-

Telpon

-

E-mail

-

Whatsapp

-

Skype

-

Ndhuwur